Robust Engineering Australia is proud to introduce it's new Aluminium Sand Casting Design & Manufacturing Project Management Services within Melbourne, Victoria, Australia.

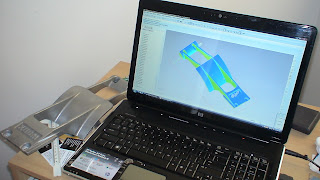

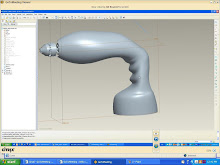

We are using our own state of the art Pro engineer CAD/CAE design software. We have used this software to produce several hundred quality casting components over the last 7 years, designing and delivering the product within record time and within the allocated budget.

We can produce the same casting design services for your future projects in a cost effective manner within your time and budget.

We guarantee you the best outcome through our efficient design services and high expertise with Pro engineer CAD systems. Our competitive prices and timely delivery of solutions will assist you to win business over your competitiors. We fully guarantee to deliver your design within the agreed time frame. To find out more about our guarantee, please contact Lucky through

lucky@robust-engineering.com.au

Our service includes :

lucky@robust-engineering.com.au

Our service includes :

- 3D Casting Engineering Modelling & 2D Drafting Services.

- 3D Pattern Designs and CNC Tool Path assistance.

- Design Jig & Fixtures and 2D drafting.

- Complete Tooling guidance throughout to manufacture your cost effective casting patterns.

- Precision Casting and Assistance to Manufacture your Final Machining Component.

Since 2002, we have been working with leading engineering companies who design and manufacture automotive components all around the world. We assist them to develop 3D design modelling; casting pattern designs manufacturing; and jig & fixture design drafting.

A signifciant number of projects involved high level 3 - 5 Axis CNC manufacturing tool paths for it's component manufacturing.

We successfully project managed and produced several hundred quality Aluminium, Nodular Iron casting through an Australian company within record time frames and budget. We serviced

companies within Automotive, Industrial, defence and motorsport.

As we have started a new venture in Northern region of Melbourne, Victoria, Australia to serve Australian companies. We will work directly with you and project manage your design project, utilizing our strong connections with leading chineese Aluminium casting technologies. We can also do the same to manufacture your precision casting part through leading CNC manufacturers, who specialise in casting technologies and precision CNC manufacturing.